obc file (I did the guitar and text as pockets with a 0.1mm endmill, and the outline as a Outside Cut 1.5mm deep) - then you can edit the Toolpaths on the right to get an idea of the settings I used. ) > Go to -> File -> Open Workspace to open the. (Unless you go for paid options like Vectric, and do a V-Carve using a vbit - the tiny point on the v-bit using a vcarving algorithm can do it)Īttached an openBuilds CAM workspace export (obc file - zipped to allow upload on forum. This tiny detail will need a really tiny endmill, and then this job - especially in the 8x mass production sheet, will take a really long time After this step, Im using Inkscape to brush up the image, create paths and generate g-code by using 2 extensions dxf file using Inkscape Ok muchas gracias ya miro a.

This, it not really a project that can be executed well, by milling, the detail is too small. Laser workspace - These are essentially the stock size plus the margin Specifically, I use a fork by the user Turnkey Tyranny available here Laser Basics Inkscape Add Patterns It uses a 2 It uses a 2.

#Inkscape gcode genereator code#

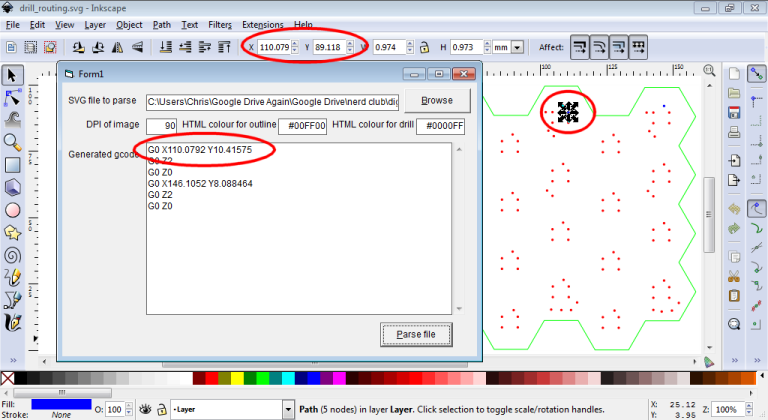

I understand the difference between bitmap and vector images and the need to set the path correctly. You dont need to write any code to create a simple story with Twine, but you can extend your stories with variables, conditional logic, images, CSS. The current version of Inkscape (. It won’t give you the powerful part manipulation features of a CAD program but it is a comfortable working environment for artists or designers that may be more used to Illustrator, Canvas, Xara or similar art packages. I know that everything must be in one layer. Inkscape is a popular, free and easy to use vector graphics editor. Perhaps Gcodetools now works differently. Artwork needs to be appropriate to the tooling, or vice versa. Essentially this is a 3-stage process: (1) choose a virtual tool (2) create orientation points (3) generate G-code. Keeping it simple helps the parsers understand the file with less fuss) For DXF the best is to convert to Polylines. Some other types work too, but if you want to play it safe, convert to Paths.

I have modified this extension to make it better and easy to use. The original inspiration came from this video by Teaching Tech where he showed the method to generate GCODE using Jtech Laser Inkscape extension.

#Inkscape gcode genereator how to#

PATH data is vectors that can be 'followed by the machine'. Draw 3D is an open-source extension for Inkscape 0.9 that lets you generate GCODE which will enable your 3D printer to hold a pen and draw. Step by step how to use inkscape to generate g code for any picture and draw it on cnc 3018 machine. Just need to use a really small endmill to create operations (endmill needs to fit into the part you are trying to cut out for example) Select all in Inkscape -> Path -> Object to Path did the trickģ) After converting it to Paths, it opens fine in OpenBuilds CAM. Or laser would be the best bet actuallyĢ) Your SVG was not converted to Paths. 1) Looking at your file, this is some tiny detail! Gonna need like a 0.1mm endmill to do the lettering.

0 kommentar(er)

0 kommentar(er)